First are short one handed spears.

A short spear would not be much different from the javelins - in fact if you only follow the same guide but make it a bit bigger (f25 core and say 1.2-3sm size) and you will get a nice dual purpose weapon - stabbing spear that you can also throw when needed.

Next are full sized fighting spears - you can use those with either 1 hand or 2 hands but they are usually not suitable for throwing. This guide is about them.

Finally you got pikes - 3 meters+. Pikes are a dedicated formation weapon, making them would be a problematic, let alone finding enough people for a pikemen square. Never encountered it so I got nothing to say about pikes.

So how would you got about making your basic simple spear? First of all materials needed.

BUDGET: around 20$ - the large pipe is a bit expensive.

MATERIALS

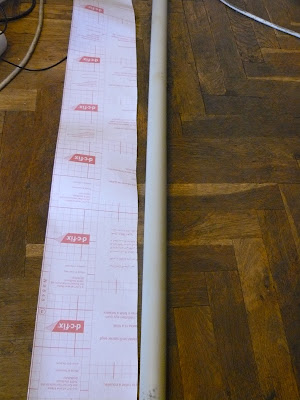

Core is an F32 polypropilene pipe, a piece of foam, tapes and some wood textured wall paper to decorate the spear shaft.

Note. The problem with polypropilene for long weapons, is that the longer the core, the more wobbly it becomes, effectively giving the so called spaghetti spear effect. The simplest way to counter that is to use a thicker pipe for a longer weapon and it works to a point. For weapons up to 1 meter something - f20 and f25 pipes are ok, for up to 1.5 meters f 32 is ok, but for bigger, its not enough and the f40 diameter pipe is I'd say a bit too big. The wobbling in spears and polearms can be solved by inserting something else inside the core - basically that's why I postponed making the spear guide, I was looking for something suitable. Alas I found nothing so far so i'll show it in the polearm guides later on.

Tools are the usual for every larp weapon.

A spear is actually remarkably easy to make, finding a suitable core is harder.

First thing to do would be to prepare the spear shaft. The core is 2 meters long and a suitable piece of wallpaper is cut for it.

And then wrapped around....After all it should look like a spear right?

Here's the shaft in full size. Can't take photos of it elsewhere - its too long.

The rear end I covered in tape. Some folks might turn it into a spike and thus make both ends of the spear useable, I'll pass on that for now.

Next thing to do is the spear head. NOTE This is a SPEAR - not a polearm, not a naginata - a SPEAR. Its meant for stabbing only, not cutting and slashing, so don't try to wallop the other guy over the head ok?

Now that we got that bit out of the way, back to the spearhead. Obviously, since you will be stabbing all the time, not occasionally as with swords, the head needs to be reinforced. You can't get away with something the size and thickness of a sword blade&tip.

Thus the spearhead will be thicker and with a fortified tip - I got 3 layers of foam on it, and then the final one giving it the pointed shape.

After the foam layers are placed on, the final two pieces are cut to give it a pointed edge. Not too much since constant use will flatten it anyway, just enough to make it look decent.

With the spearhead finished you only need to cover it in tape and its done.

There is you basic spear in full size.

14 коментара:

So awesome =)

Here in Rio de Janeiro - Brasil, we use EVA, to make our weapons. They look more realist, not something like latex, but really cool anyway.

I'm a armorsmither and weaponsmither here, if you want a tip, send me a message.

See ya,

Stígandr Stormson

So show what you have to see if there is useful info :). I'm a blacksmith, maille artisan and weapon crafter myself.

How would you do a Trident?

Hmmm...now there you got me. Never though of making a trident actually. I'd say best bet would be to use the bardiche/axe head making technique to make the 2 prongs.

I use pipe and fixens make sure to glue the fixens tight and foam everything

could you use a wooden rod for the shaft or would that be to hard?

Best not -a wooden rod for core is a bad idea.

Why not wood?

Because wood may snap/splinter and has a much higher chance to bruise.

Thank you! This guide was super helpful!

For core: how about using a heat gun to warm up the pipe until pliable, then push a second pipe whose outer diameter is the same as the first's inner diameter inside?

What is the diameter of the pipe you used for this?

32mm pipe.

Post a Comment